By DAVID E. CARROLL

EAA 373878

1713 Live Oak Dr.

Kennesaw, GA 30144

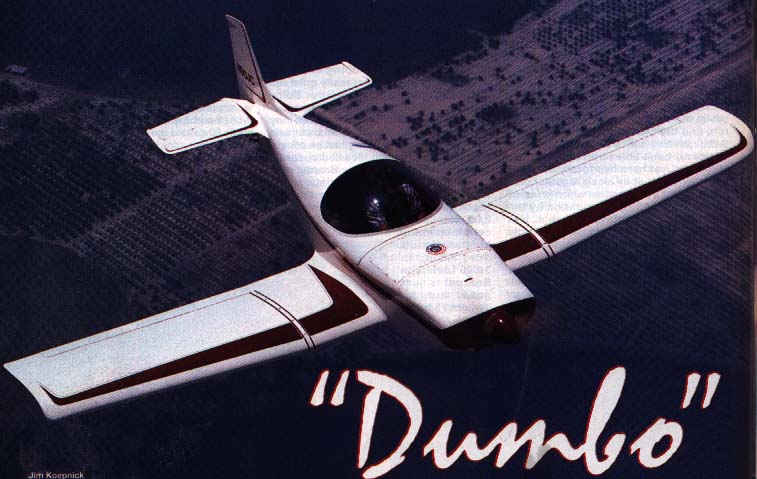

Construction of my KR-2, N90JC (aka "Dumbo"), began on March 1, 1986 and received its airworthiness certificate on February 26, 1991. I had very little experience in taildragger aircraft so I spent the following month performing 30 hours of slow and high-speed taxi testing along with extensive engine testing. The joke going around the airport at the time was "if that guy had wanted only a go-cart he could have saved a lot of money and time, but all of that testing paid off on March 23, 1991 when I made the first flight of my KR-2.

To prepare for my first flight, I was checked out in a C-140 and spent 5 hours doing nothing but takeoffs and landings as well as making mental notes of emergency landing sites around McCollum Field. Although a C-140 is a taildragger, it does not fully prepare you for a KR-2 and should be considered a "minimum" to gain ground-handling experience.

Once airborne on the first flight, the KR-2 flew very nicely with smooth control response and no surprises. Pitch control was sensitive, but once I released my death grip on the control stick and flew with minimal finger pressure, everything smoothed out real nice. The landing gear stayed down and locked for the first two flights until I was sure all the bugs were worked out of the airframe and engine. The only problem that required attention was a high cylinder head temperature on climb-out. This problem was quickly solved by enlarging the air exit on the bottom of the engine cowl.

Power is supplied by a homebuilt 2100cc VW engine turning an Ed Sterba 52x54 swept blade prop. In the first year of flying my KR, I have accumulated over 120 hours of flight time. The VW engine has performed flawlessly since the beginning. The only problem I have encountered is with the Slick magneto, but it was old to start with.

At 3000' over Cartersville airport the engine started missing, got progressively worse and then finally gave up. The emergency landing was uneventful and the KR handled very nicely while setting up a one-shot final approach and gliding towards the runway below. I spent many hours diagnosing the problem but found nothing wrong and I was unable to duplicate the problem.

The next morning I fired up the KR and after a very thorough engine run-up, proceeded to home base only 15 minutes away.

Several days later I aborted a take-off because the engine started missing again. It was back to the hangar for Dumbo. This time I started diagnosing the problem without removing anything except the spark plug wires. Sure enough, the magneto was not producing a good hot spark and sometimes no spark at all. I disconnected all the wires from the P-lead and then reconnected them back. The magneto was now producing a good, hot, flat blue spark every time. I still do not know why disconnecting a wire and then reconnecting it back "temporarily" fixed the magneto but, needless to say, within minutes I was on the phone ordering a new Slick magneto. A secondary electronic ignition is also in the works for my VW engine. Carburetion is through a "Super Carb" from Mosler Motors. This modified 32mm Posa with mixture control has been absolutely trouble free once I was able to dial it in correctly. The engine starts within 2 or 3 swings of the blade every time whether it is 32 degrees F. or right after a quick refueling stop on a hot day.

During the construction, Rand Robinson Engineering Co. provided exceptional builder support and prompt shipment of all parts and supplies. Jere Rosser and Bob Muse, ex-KR-2 builders and now KR-2 pilots, also provided me with answers for any and all questions I could bug them with. My greatest supporter throughout the project was my wife, Karen. She sanded the foam wing cores and then vacuumed the house twice a day for an entire month trying to collect all of that foam dust. I would spray primer and, you guessed it, she sanded and vacuumed some more! I kept telling her that spraying primer was the hard part but she did not believe me. The following day she was spraying primer and was sanding/vacuuming. I could not let this continue any longer so after telling my friend Chuck Latkoff we had just stocked up on his favorite beer, I was able to ease my sanding duties.

Truthfully though, Chuck provided almost all of the technical assistance, all of the neat sanding and painting equipment and many hours of hard labor to help ensure the KR would look as good as it flies. Without his help I probably would still be sanding today. I tried to keep my KR-2 as close to stock as possible but could not resist the urge to change a few things. The horizontal and vertical stabilizer tips are modeled after my Dirty Birdy R/C pattern plane as well as the strakes.

Wing incidence was changed slightly with the goal of producing a more efficient cruise attitude. The plans call for +3.5 degrees at the wing root and +.5 degrees at the wing tip. My KR has +2.25 degrees of wing incidence at the root and washes out to O. degrees at the wing tip. Stalls are gentle and straight ahead with neither wing dropping. Stalls occur at 35 mph IAS which works out to be 43 mph TAS.

I have also moved the VW engine, equipped with a full electrical system, 5" further forward to get the C.G. right where I wanted it without adding any additional weight. This modification has proven beneficial to me as this "more forward" C.G. location has improved the KR's ground handling. Even after 175 landings I find myself still learning to fly taildraggers. The KR-2 has very nice landing characteristics but just as all taildraggers go, you have to be in control right up to the hangar door. If I relax on landing roll-out it becomes a game of catch up or be caught and you do not have long to get it together. I ground looped my KR once and it took less than a couple of seconds for my whole day to be ruined. After the ground loop I decided to move the engine forward and to only fly with the C.G. in the front 6" of its designed 8" range. For myself, a low time taildragger pilot, this has helped me keep it on the runway.

Inside my KR-2 is a dual stick control system originally designed by Jere for use in his KR-2 "Tweety Bird." The dual stick is fairly simple to construct, looks great and provides a great feel for control surface deflection. As part of the dual stick system, an elevator push-pull tube runs from the center of the dual stick system to a bellcrank located in the center of, and on the back side of the aft wing spar. From this bellcrank are the conventional control cables going to the elevator just as the plans call for.

Another modification is a 13.5 gallon aluminum header fuel tank, welded at all seams and over all rivet heads, with a removable panel on top. The removable panel allows for easier access to the fuel tank (which can be lifted straight up through the opening), instrument hook-ups in the instrument panel, rudder pedals and their associated cables and the retractable landing gear system. It is easier to add this removable panel while you are building your KR than it would be to cut through your nice paint job should any problems arise underneath.

The stock retractable landing gear has operated flawlessly and has withstood some landings that I do not dare mention to any of my flying buddies for fear of being tossed out of the hangar head first. The only modification I utilized was to trim 2" off each end of the landing gear spring bar to bring the gear legs closer in. This will allow the gear system to absorb slightly larger landing loads, i.e., hard bounces, and it really works.

Initially, three coats of Featherfill were sprayed and sanded between each coat. We sanded about 95% of the Featherfill off as the objective was to only fill the fiberglass weave and small staple holes in the fuselage. Next we sprayed two coats of DuPont primer with UV protection, again sanding between each coat. A final sanding session ensured a smooth surface as this is the controlling factor in your final finish. Your finish coat, or color coat, will not hide any imperfections left untreated up to this point. Before we sprayed the finish coat a single coat of sealer was applied and allowed to cure one hour and become tack free. After a little more surface preparation three medium-wet coats of the acrylic enamel finish paint were sprayed and allowed to cure for 24 hours before handling. With regards to the elephant on the side, it symbolizes "Dumbo" the flying elephant. My two sons figured that if Dumbo could fly, then Daddy's plane could, too. It made sense to me!

The performance of my KR is a little under the published performance statistics but fully meets what I had expected. Empty weight is 608 lbs. which is a little on the heavy side and most likely accounts for some of my decreased performance. I could probably shave 50 lbs. by sanding off several layers of paint. Actual performance for my KR-2 (with the original 52x52 Ed Sterba prop) is stall at 35 mph IAS, max. cruise is 155 mph and maximum speed is 165 mph. Fuel consumption at 5,500', 3100 rpm and 135 mph IAS is 3.6 gph. My advice to anyone currently building a KR or wanting to get involved in a KR project is to keep it light (500-550 lbs.), stick to the plans and not too much paint. Assuming good craftsmanship and a strong VW engine, the first two rules will ensure your KR-2 will be fun to fly and not one to collect dust in the hangar between flights. The third rule would have saved me a month of work and $400. I fly my KR-2 an average of two hours each week because it is reliable and, best of all, it is flat out fun to fly! I take my two sons and my wife flying whenever they have spare time, which my wife says she does not have much of because I am flying all the time.

Rand Robinson offers an excellent 2 seat sport plane that is easy to build, cost efficient and a pure joy to fly. They also have the service and builder support to back it up. This is the first aircraft I have built and I was very pleased with the quality and clarity of the construction manual, blueprints and parts that were supplied. If Rand Robinson offered a larger version of the KR-2 that could seat 4 people and incorporated a tri-cycle landing gear, I would be the first in line to build one.

I would like to thank Jeanette Rand for her support along with SPORT AVIATION magazine, Aircraft Spruce & Specialty, Mosler Motors, Great Planes, Ed Sterba, the folks at Alexander Aeroplane and all of my family and friends for contributing to the success of my KR-2.